Abstract

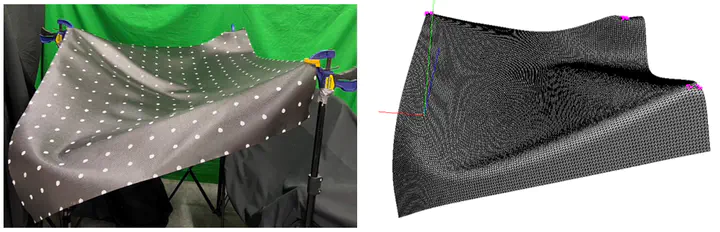

The composite sheet layup process involves stacking several layers of a viscoelastic prepreg sheet and curing the laminate to manufacture the component. Demands for automating functional tasks in the composite manufacturing processes have dramatically increased in the past decade. A simulation system representing a digital twin of the composite sheet can aid in the development of such an autonomous system for prepreg sheet layup. While Finite Element Analysis (FEA) is a popular approach for simulating flexible materials, material properties need to be encoded to produce high-fidelity mechanical simulations. We present a methodology to predict material parameters of a thin-shell FEA model based on real-world observations of the deformations of the object. We utilize the model to develop a digital twin of a composite sheet. The method is tested on viscoelastic composite prepreg sheets and fabric materials such as cotton cloth, felt and canvas. We discuss the implementation and development of a high-speed FEA simulator based on the VegaFEM library [29]. By using our method to identify sheet material parameters, the sheet simulation system is able to predict sheet behavior within 5 cm of average error and have proven its capability for 10 fps real-time sheet simulation.