I am a Lead Robotics Engineer at GrayMatter Robotics, where I develop advanced AI-driven solutions for the perception and planning stacks that power our robotic platforms to operate autonomously and reliably in high-variability, unstructured environments.

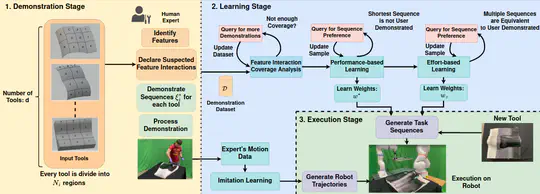

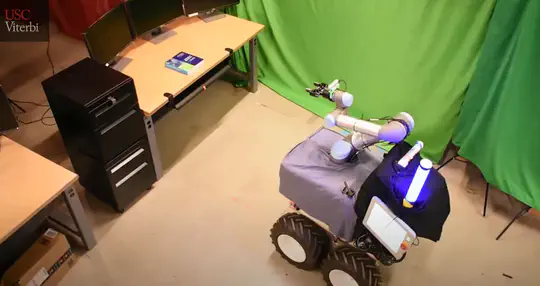

Previously, I earned my Ph.D. in Robotics from the University of Southern California, where I was part of the Realization of Robotics Systems Lab (RRoS), advised by Dr. Satyandra K. Gupta. My research focused on integrating physics-informed learning methods into robotic manipulation, with an emphasis on generalization, intuitive physics-based reasoning, and data efficiency in handling complex deformable objects ( Link to Dissertation ).

Before my Ph.D., I led multiple industry-funded projects at USC as a Master’s student and worked as a Robotics Engineer at Rolls-Royce in Singapore for two years.

Download my CV .

- Robot Learning

- Robotic Manipulation

- Deep Learning

- Motion Planning

PhD in Mechanical Eng. (Robotics), 2025

University of Southern California

MSc. in Mechanical Eng., 2021

University of Southern California

Bachelor of Technology, 2016

National Institute of Technology Karnataka

News

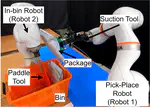

- Nov 2025 Our paper on a mobile robotic system for screwdriving in unstructured environments has been published in Robotics and Computer-Integrated Manufacturing. Link

- June 2025 Attended the Robotics Science and Systems Conference at USC in LA, where I co-authored a paper at the Space Robotics Workshop Link

- June 2025 Started working at GrayMatter Robotics as a Lead Robotics Engineer

- May 2025 I defended my Ph.D. thesis titled Physics-Informed AI Methods for Deformable Object Manipulation

- Apr 2025: Our paper on real-to-sim parameter learning for thin-shell deformable objects is accepted at ASME IDETC-CIE 2025 Conference Link

- Oct 2024: I am selected as one of the finalist for the Amazon Robotics Fall Research Symposium. I will be presenting my work on physics-informed learning for deformable object manipulation, in-person at their Boston office Link

Experience

Research

Featured Publications

Publications

Projects